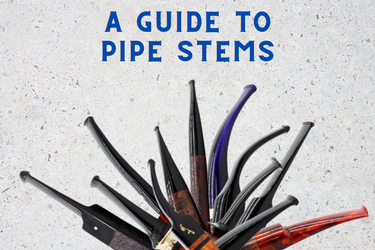

A Guide to Pipe Stems

Posted by Greg Roesnberg on 20th Sep 2023

Table of Contents:

Materials

Styles

The stem of a tobacco pipe is perhaps the unsung hero of the apparatus. It defines our smoking experience in ways that are easy to overlook.

Like much of pipe design, stems are tasked with satisfying both aesthetic and functional demands.

A picture frame must be well constructed, with hardware well secured and able to bear the appropriate weight. It has to be aligned to keep the picture level. But the utility is hardly worth it if the frame doesn't serve what it's framing, if it ostentatiously clashes, or has awkward dimensions. This is similar to the purpose of the pipe stem. To serve a function in facilitating a good smoke while giving aesthetic balance that complements the bowl.

Of course, each pipe smoker has has their own preferences when it comes to meeting these standards. In fact, multiple preferences can exist within that one smoker, opting for that statement-pipe one day and the humble one the next—perhaps a softer material for situations where clenching is ideal. The right answer can only come from your experience, as it will be what feels and looks right to you, but it doesn't hurt to have some background to help you navigate these preferences.

Pipe Stem Anatomy

Let's start with the parts of the pipe stem. Terminology can vary, so I'll mention some of the other terms you may here, but we'll stick to the illustrated terms in this piece.

- Stem - The entirety of the appendage from one end to another. This may also be called the mouthpiece (more of a Britishism according to some sources).

- Tenon - The tenon is the cylindrical piece that protrudes from the face of the stem and inserts into the mortise. The push tenon is most common, but some are threaded (screw in).

- Draft hole - The draft hole is the channel that carries smoke from the chamber to the end of the stem. This may be referred to as the bore, airway, smoke channel, and probably some other intuitive names.

- Bit - The bit refers to the very end of the stem opposite the tenon. This is also called the button or lip.

- Slot - The slot is the opening of the draft hole specifically on the bit end, where the draft hole usually fans out, or is "slotted."

Pipe Stem Materials

Historically, pipe stems have been made from many materials, but the two that are most common today are ebonite and acrylic.

Ebonite (Vulcanite)

Ebonite refers to hard, or, vulcanized rubber. Much like "band-aid" and "jello," ebonite is a genericized trademark—a term broadened from its origin as a brand of hard rubber to now being used to describe the material more broadly. We will use ebonite here to describe the material, but it may also be called vulcanite. In fact, it's hard to say which is the de facto prevailing term. But just know they are synonymous.

That said, I've noticed—as have others—that vulcanite might be favored when speaking of cheaper hard-rubber. But that's far from a rule to apply when hearing one talk about vulcanite without verifying context.

The quality of ebonite is certainly of concern to the pipe smoker. Of the two widely embraced stem materials (ebonite and acrylic), there are differences to consider. Ebonite is softer—it's supple and therefore much easier on the teeth, especially when clenching. But due to the sulfur content, ebonite is notorious for oxidizing; dulling and developing a light, sometimes greenish discoloration, especially around the bit where the mouth comes into contact.

However, higher quality ebonite with less sulfur content is more available these days. This higher purity ebonite doesn't oxidize, or at least it does much slower and fainter, especially when taking some preventative measures. Not a certainty, but you can mostly expect the quality to track with price range for new ebonite stemmed pipes. To keep the price down, more affordable lines often use less quality ebonite. But you can still minimize oxidation.

Caring for ebonite stems

A good rule for ebonite stems, especially those that are more prone to oxidizing, is to avoid storing in direct sunlight. You can also regularly apply a solution such as Briarville No Oxy Stem Oil, which is a preventative treatment that slows the rate of oxidation.

Ultimately you can treat oxidation, but it's something you don't want to do more often than is necessary. Personally, I don't mind living with some oxidation, especially with my cheaper pipes. It seems like a fair trade off for the price point, and it's only once the oxidation is significant that I notice it affecting the flavor. Though I generally try to deoxidize before that point.

For light oxidation, I'll wet a magic eraser with water and rub the affected area, or wet sand with micromesh pads.

This method generally gets the job done for regular maintenance, as I don't let the oxidation get too bad.

To get rid of heavier oxidation (generally, this will be estate pipe restoration, but sometimes oxidation-prone stems), I soak the stem in Briarville Oxidation Remover, which brings the oxidation to the surface to be wiped with cotton pads and 91%+ alcohol. I'll start with about one hour of soaking and re-submerge if necessary. If the stem has an insignia, I'll cover it with petroleum jelly, as the solution can eat away at the paint. When satisfied, I'll bring back shine with microfiber pads. You can do this with lighter oxidation, but be especially cautious not to leave the stem soaking too long.

Cumberland (Brindle)

You may hear brindle—or more often, cumberland—referenced as a stem material. However, this isn’t so much a material as it is a style, distinguished by the swirl of color resembling wood grain.

Cumberland takes its name from the Dunhill Cumberland series that popularized the style with a dark red accent. These stems are also represented in Dunhill's Chestnut and County finishes.

Traditionally, Cumberland stems are ebonite, although it’s often noticed that they (or colored ebonite in general) seem harder than most black ebonite stems. It's proposed that the chemical makeup of the colored ebonite material that is extruded into a single rod may lend to this, which makes sense enough but I'm no authority. These stems also seem less prone to oxidizing.

However, acrylic stems, which often tout colorful hues, may also have a cumberland-like design. The Savinelli Morellina line is a good example of this.

Acrylic (Lucite)

Then there are acrylic stems. Acrylic does not suffer from the same propensity to oxidize like ebonite does, making it exceptionally low maintenance. However, acrylic is much harder than ebonite, and can be disfavored for being less comfortable. This is especially so when clenching, or, holding the pipe by only the teeth, but even when supporting the pipe with the hand, many find the give of ebonite more agreeable.

Distinguishing ebonite and acrylic pipe stems

From appearance, black ebonite and acrylic aren't so easy to tell apart. Acrylic has a bit more of a natural shine and you can usually see your reflection in it. That may be the best indicator by sight, but some nicely polished ebonite can be tricky.

Simply pointing out that one is softer isn't so helpful, it's all relative, and again, ebonite can sometimes seem uncharacteristically hard, especially colored ebonite stems. I find tapping my nail against the material is often more illuminating, as ebonite gives more of a *thud*, acrylic a *clink*. I know, very scientific.

Last, and maybe most effective, rub the stem in one place with your thumb and smell the stem. Does it smell like hot rubber? That's ebonite.

Plastic

These days, plastic stems are mostly found on Missouri Meerschaum pipes, the historic corn cob pipe company.

Their lower end pipes use plastic stems that are soft and easy on the teeth and keep the price low, fulfilling that corn cob pipe role as great smokers anyone can afford. Despite sometimes being thought of as disposable, even the cheap cobs can last years. And for stems that really last and look great, often in wonderful color schemes, they offer acrylic stemmed corn cob pipes in a slightly higher price point.

Some less common pipe stem materials

- Bakelite - Not so common today, Bakelite is a hard plastic, usually with a yellow tint.

- Carbon Fiber - The Turkish Meerschaum pipe carvers at Altinay Pipes make their Meerschaum Pokers' rod stems from carbon fiber. You could just as well call these shanks, as they insert directly into the bowl and are fixed at one end with a short acrylic stem.

- Metal - Another stem material you will find on certain rod stemmed Pokers such as the Nording Compass or Star Meerschaum.

- Bamboo - Though a common stem accent, the only absolute bamboo stems you're likely to see these days are on Old Dominion corn cob pipes. Old Dominion was founded in 2013 by brothers Bob and Bill Salvage. They successfully set out to make traditional corn cob pipes with bamboo rod stems, a convention of cob pipes that had long been a thing of the past. They are now made by Missouri Meerschaum.

- Amber - most common on Meerschaum pipes from time ago. Estate pipes with apparent amber stems may be imitation amber. According to William Augustine’s Tobacco Leaves (1915), “by far the largest quantity of amber used for ordinary pipes is imitation amber. The manufacture of this is a trade secret. It is so good and fulfills its purpose so well that only experts can distinguish it from genuine amber. There are many substitutes for amber.”

Pipe Stem styles

When it comes to the actual shape of a pipe stem, the scant terms we use to categorize belies the breadth of diversity there is in stem shaping. Pipe makers thoughtfully shape stems to give balance in comfort and aesthetic to the overall design.

Straight vs Bent Pipe stems

The most basic way of classifying a tobacco pipe stem is whether it is bent or straight. The terms don't need much explaining, but there are implications for both that may factor into one's preference.

Once shaped, those destined to be bent stems are heated up just enough to make the material pliable. This takes tact—not hot enough and the stem could snap, too hot and it could soften and lose structure. Once the ideal bend is achieved, the stem is usually dipped in water, cooling it and thus setting the bend.

Some bends are dramatic, others show the subtlest down turn, so you'll often have them specified as slight, half, or full bent.

Straight stems are more amendable to passing a pipe cleaner, i.e., getting the cleaner all the way from the slot to the chamber without separating the tenon from the mortise. Since you don't want to separate the two while the pipe is still hot, this is convenient for absorbing moisture and clearing build-up mid-smoke or immediately after.

Bent pipes on the other hand often make for great clenchers. Because of the downward weight distribution, you might be surprised at the sizable pipes that can comfortably be clenched.

The exceptions are many. There are surely straight pipes that don't pass a cleaner due to narrow or imperfect drilling. In contrast, plenty of well made bent pipes will pass a cleaner. There are light straight pipes that are great clenchers—sometimes due to their petite size, but some average sized pipes can surprise you with their lightness.

Fishtail vs P-lip

Most tobacco pipe stems have fishtail bits, which see an inflated ridge at the bit. It's a simple design to the eye, but when the bit is just a little too big, the feel in the mouth can be awkward. Too small, and it doesn't seem to offer the intended support, especially when clenching. There's a subtle art to shaping the bit that is easily taken for granted.

The P-lip is a patented design from Peterson pipes. The round slot at the top of the bit directs smoke toward the roof of the mouth with the purpose of reducing tongue bite. The drawback with P-Lips is they are somewhat cumbersome to clean, but they offer an experience of their own that many swear by.

Saddle vs Tapered

The terms tapered and saddle as they apply to pipe stems describe how the stem narrows from the tenon-end to the bit. Tapered refers to those that gradually narrow down the length of the stem. Saddle stems will narrow abruptly from the continuity of the shank's width. Some designs feature a mix of tapered and saddle, often called a combination stem.

There are also diamond shaped stems, which may be saddle or tapered. Diamond shanks and stems are often associated with the Bulldog shape, being its defining quality from the Rhodesian, but the diamond stem certainly isn't exclusive to the Bulldog.

Military Mount

Taking our attention back to the other end of the stem, we have a departure from the traditional tenon system. Also called an army mount, this design features a stem that tapers in on the would-be tenon end, which communicates with the mortise for a tension fit. The shank will most likely be reinforced with a band, insuring it against cracking from the pressure of the tension fit. In addition to being a handsome style, the physics of this system allow for removal of the stem while the pipe is hot without the risk of damage that the traditional tenon fit imposes.

Like so much in pipe smoking, we have a number of broad terms to best describe a world of nuance and style. In navigating your own pipe stem preferences, keep your mind open, and always consider why something is working. Sometimes it's an anomaly—that pipe that almost always delivers a great smoke for no discernible reason. But often, part of what's working for us are small factors we don't immediately consider that we would do well to integrate into our choosing of pipes going forward, such as that brand whose bits just feel right for you, or the draft hole dimensions for your ideal draw.